Hyter: Green hydrogen generation through electrolysis

01 April 2024 - Corporate, Projects, SolutionsHyter manufactures a range of electrolysers using an innovative technology: AEMWE anion exchange membranes. This solution guarantees a significant series of technical and environmental advantages, as well as a reduction in the costs of plant management.

Based in Desenzano del Garda (Brescia-Italy), Hyter was acquired by the Pietro Fiorentini Group in 2011.

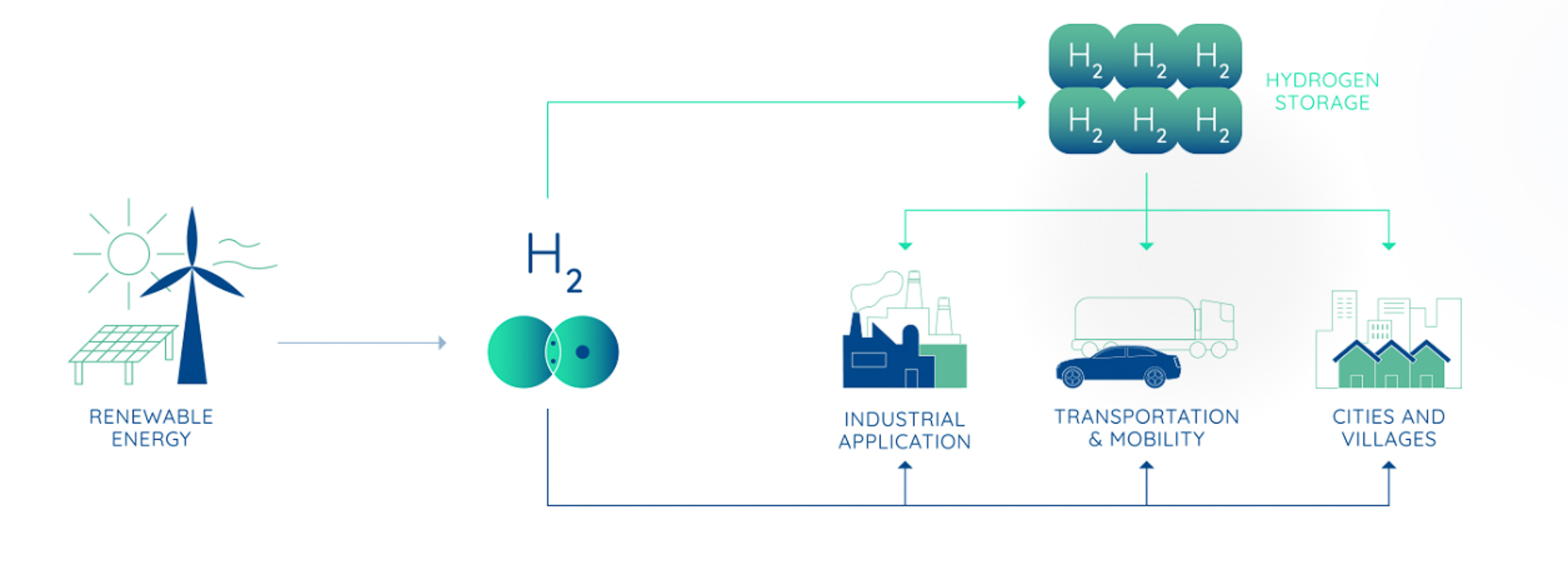

Electrolysers for hydrogen generation are Hyter’s core business. Hyter carries out modular and customised projects to cover the needs of different sectors, such as industry, mobility, or isolated grid systems.

AEMWE TECHNOLOGY (Anion Exchange Membrane Water Electrolysis)

Specifically, Hyter’s offer includes solutions for the generation of green hydrogen, i.e. hydrogen produced from renewable energy, through the electrolysis process of water, using an innovative process based on anion exchange membranes (AEMWE) instead of the alkaline process or proton exchange membranes.

The electrolyser supplied by Hyter combines the advantages of both PEM and alkaline systems, allowing reduced investment costs and lower environmental impact thanks to reduced use of noble metals.

Ion exchange takes place through a polymer membrane produced in-house by Hyter. This membrane contains electrolytic substances that improve the efficiency of water splitting and has the function of separating hydrogen and oxygen already during the production phase.

This technology is much less expensive chemically and at the same time possesses excellent efficiency in terms of yield.

HYTER PRODUCTS & SOLUTIONS

HYTER HYDROGEN ELECTROLYSER

This device is modular, easy to install and configure, and offers great energy efficiency, thus reducing hydrogen production costs if compared to other technologies. Moreover, Hyter electroliser can be adapted to the specific needs of various industrial applications.

Hyter generators are made of AISI316 stainless steel and special plastic components.

Our solutions can be designed according to the customer’s requirements and end applications as a result of a modular architecture.

- The hydrogen produced is 99.95% pure and is already produced pressurised up to an output maximum of 25 bar without the use of compressors.

- The machine does not have a minimum operating range; it runs from 0% to 100% of its potential.

- The cooling system is sized with a chiller that cools the process water as well as cooling the hydrogen in order to increase its purity up to 99.95%.

- The process liquid is a solution of 3-5% with KOH, using ASTM type II demineralised water, and can be produced directly without energy expenditure (using water mains pressure).

Discover more about Hyter’s Electrolysers.

HYTER STACK

Hyter electrolyte cells produce gaseous hydrogen and oxygen through the electrolysis of water.

Scalable technology and modular dimensions to meet the various end applications.

- Remote electronic control unit

- Outlet pressure up to 25 bar

- Use of electrolytes (KOH) between 3% and 5%

- Metal parts made of AISI 316 steel

- Direct connection to the renewable energy sources

Hyter Stack is designed on the needs and requirements of the consumer, always keeping the end application in mind. The use of an electronic control unit ensures better management. Direct connection to the renewable energy sources.

HYTER CASE STUDIES

PLT ENERGIA: A green hydrogen plant for PLT Energia thanks to the Hyter electrolyser

With the innovative electrolyzer supplied by Hyter, a company part of the Pietro Fiorentini Group, PLT energia will be able to use green hydrogen as an energy vector to make its offices even more sustainable.

PLT energia has been presiding over the entire value chain of renewables, from the design of wind and photovoltaic plants to the direct sale of energy, for 15 years. Now, it will experience this technology for the first time to zero out the CO2 emissions of its offices and gain strategic know-how for a large-scale development.

PLT energia Srl is a company that manages photovoltaic, wind, small wind and biomass plants in Italy and abroad.

The project is centred around the acquisition of the new plant built by Hyter: a technological jewel for the generation of green hydrogen through the electrolysis of water, using the innovative AEMWE, Anion Exchange Membrane Water Electrolyser, technology.

> Visit the project in our EXPERTISE AREA.

> More project info.

SIRIUS: The Sirius project led by Hyter is among the winners of the MITE call for proposals on hydrogen research

Hyter was recently awarded one of MiTE’s calls for tenders with the Sirius project, which involves the construction within three years of the world’s first electrolyser with a size greater than one megawatt based on AEMWE technology, Anion Exchange Membrane Water Electrolyser.

The Department of Chemical Sciences of the University of Padua and MatRes will carry out the research activities aimed at improving the performance of specific components (the catalyst cells), exploiting new nanostructured materials that are also conducive to a lower environmental impact compared to those currently in use. The project will be completed by INRETE Distribuzione Energia with the construction of the experimental industrial site for hydrogen utilisation.

INRETE Distribuzione Energia S.p.A. manages the activity of natural gas and electricity distribution mainly in the Emilia Romagna region with the distribution of gas in 143 municipalities, plus 3 in Tuscany, and of electricity in 24 municipalities.

MBN Nanomaterialia operates on the promotion of innovative high-tech materials and on production of customer-specific product solutions.

> Visit the project in our EXPERTISE AREA.

> More project info.

STRAUBING: Renewable energy queens conquer Germany: work starts on Straubing pilot plant

On the 28th of July, 2022, at the Straubing wastewater treatment plant in Germany, the work to install a specific solution by MicroPyros BioEnerTec, Hyter, Biokomp and Pietro Fiorentini to research and experiment with biomethanation processes from various sources, in particular biogas and synthesis gas, was started.

All the companies involved in the design, construction and installation of the project are part of the Pietro Fiorentini Group, the main promoter of a unique research and experimentation system for biomethanation throughout Europe, thanks to which it will be possible to create gas mixtures on site and rely on the direct feeding of biogas from the wastewater treatment plant’s digesters.

Each company is bringing its own contribution. The electrolytic stack with Anion Exchange Membrane Water Electrolyser (AEMWE) technology for power-to-gas will be supplied by Hyter.

> Visit the project in our EXPERTISE AREA.

> More project info.

VISIT PIETRO FIORENTINI EXPERTISE IN HYDROGEN