Hydrogen: the ideal ally for the energy transition

30 April 2024 - Solutions, CorporateThe energy transition is based on using a clean energy mixture, including hydrogen. In response to this growing market need, Pietro Fiorentini has developed and tested a specific range of products ready to work with 100% hydrogen.

We are applying our international 80 years experience on gas networks to face this exciting challenge: from designing and testing hydrogen ready solutions up to developing new hydrogen blending stations, our purpose is to exploit the full potential of existing gas networks to accept and deliver hydrogen.

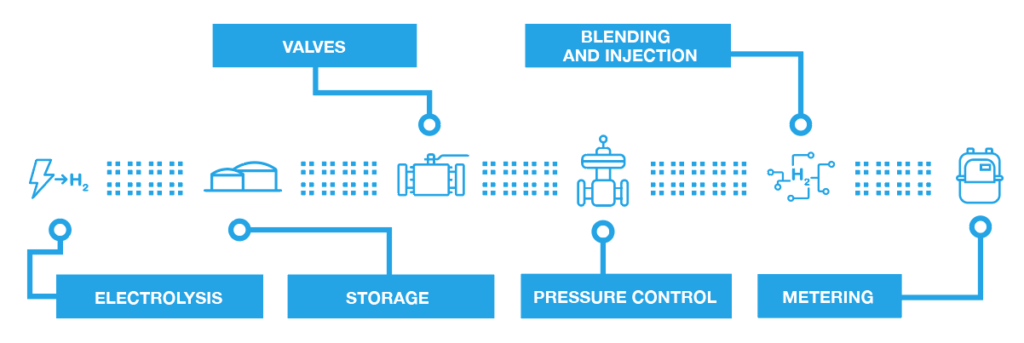

Our solutions are designed to enable new production technologies and exploit the existing gas networks for its transport and distribution. Moreover, our set of solutions spans from hydrogen generation through electrolysis up to the end users metering, passing through storage, pressure control and blending with natural gas.

100% hydrogen full range of products

As a leader in the commitment to the promotion and development of green energy, Pietro Fiorentini offers a wide range of products designed and prepared for use with 100% hydrogen, including valves, meters and regulators.

|

|

|

|

|

|

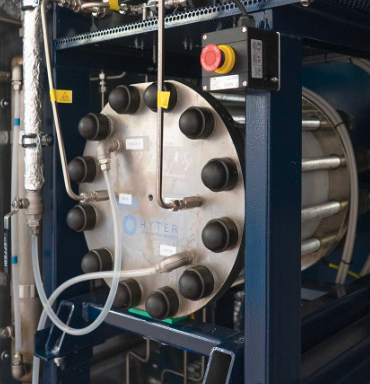

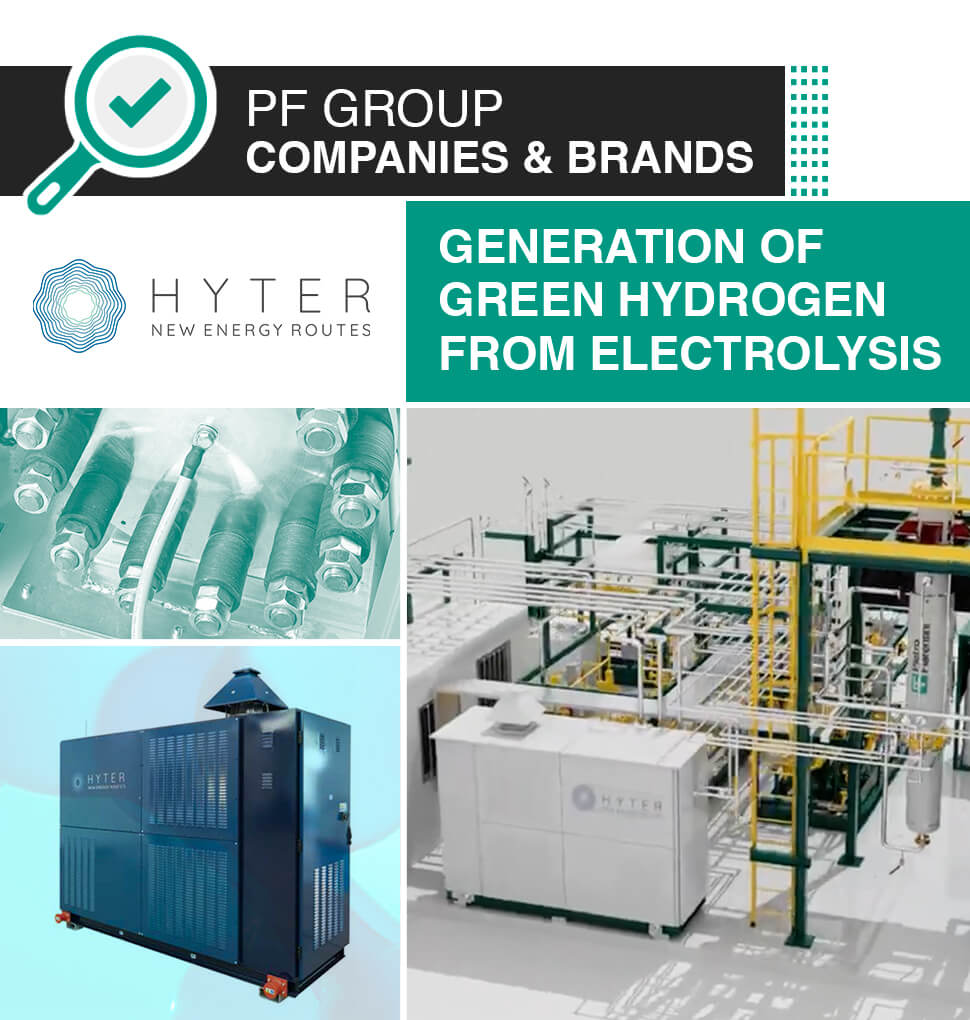

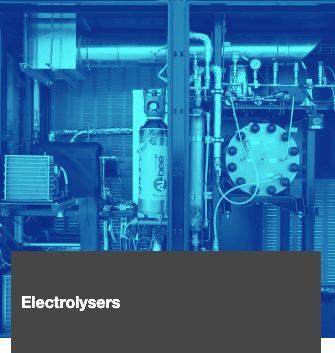

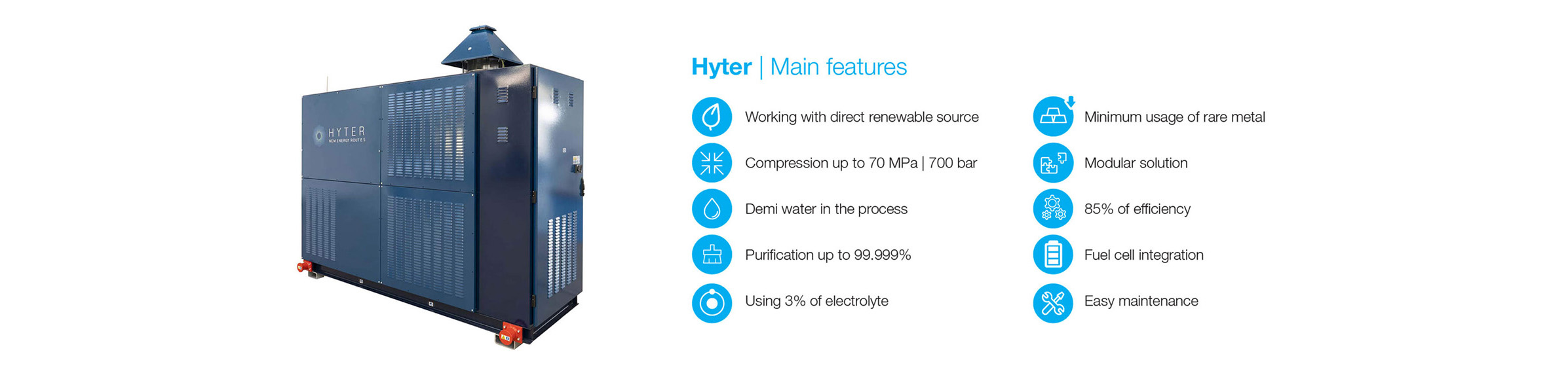

In this respect, the hydrogen electrolyser of Hyter, a company part of the Pietro Fiorentini Group, uses the advanced AEMWE technology (Anion Exchange Membrane Water Electrolysis) to produce high-purity hydrogen in a sustainable way.

This device is modular, easy to install and configure, and offers great energy efficiency, thus reducing hydrogen production costs if compared to other technologies. Moreover, Hyter electroliser can be adapted to the specific needs of various industrial applications.

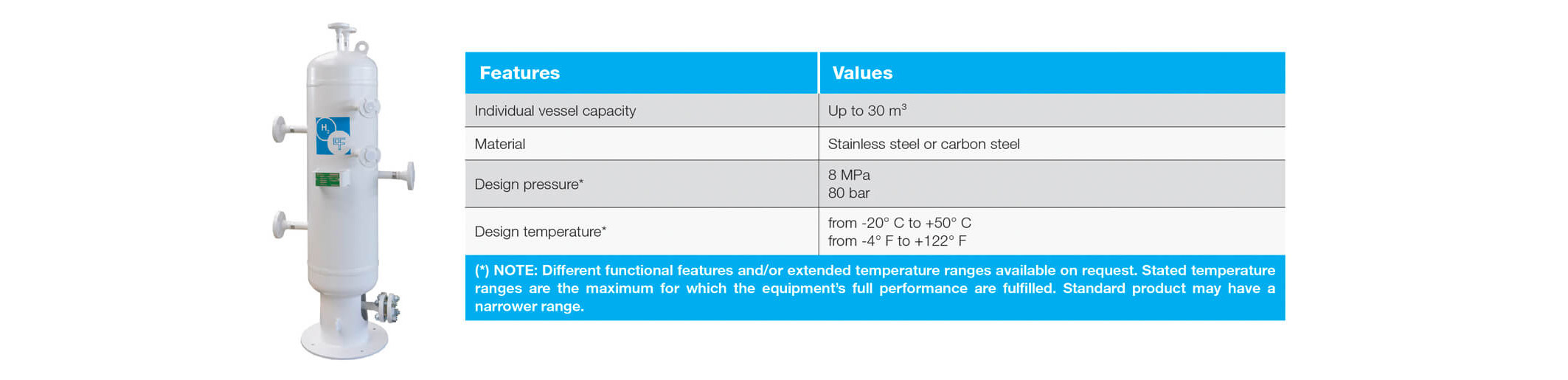

Thanks to the expertise of our team, all these traditional advantages of natural gas are applicable to hydrogen on a wide range of pressure vessel tanks, tailored on every customer’s need.

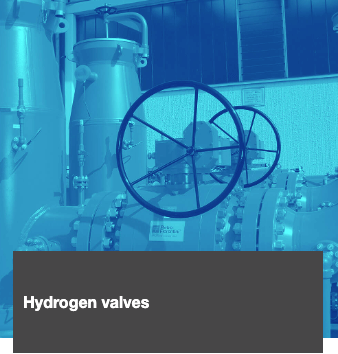

TIV Valves, part of Pietro Fiorentini Group since 2019, is an Italian manufacturer of high quality ball valves striving to be your most valuable partner for oil and gas, sustainable energy, green and industrial applications, offering on-time delivery of engineered technical solutions thanks to its specialized team of experienced managers and engineers and the 25,000 m2 production area.

Pietro Fiorentini Group guarantees the all the current manufactured natural gas valves in the following range are suitable for 20% hydrogen blending service.

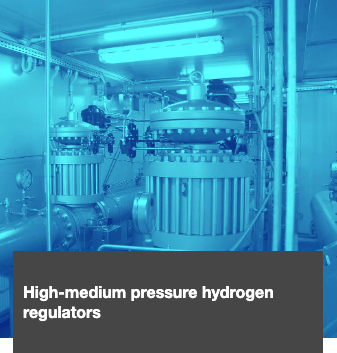

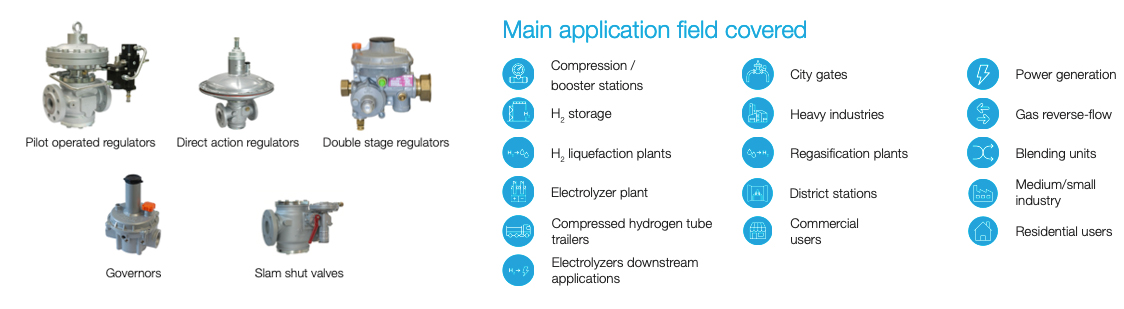

Thanks to our many decades of experience in the natural gas field, we can provide a complete range gas pressure regulators suitable for all applications, from transmission to residential. These devices are now being tested to work with hydrogen blends and pure hydrogen, in order to be ready for the future of gas networks. Pietro Fiorentini Group guarantees the all the current manufactured pressure control products are suitable for 20% hydrogen blending service.

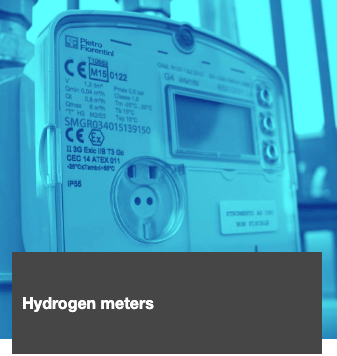

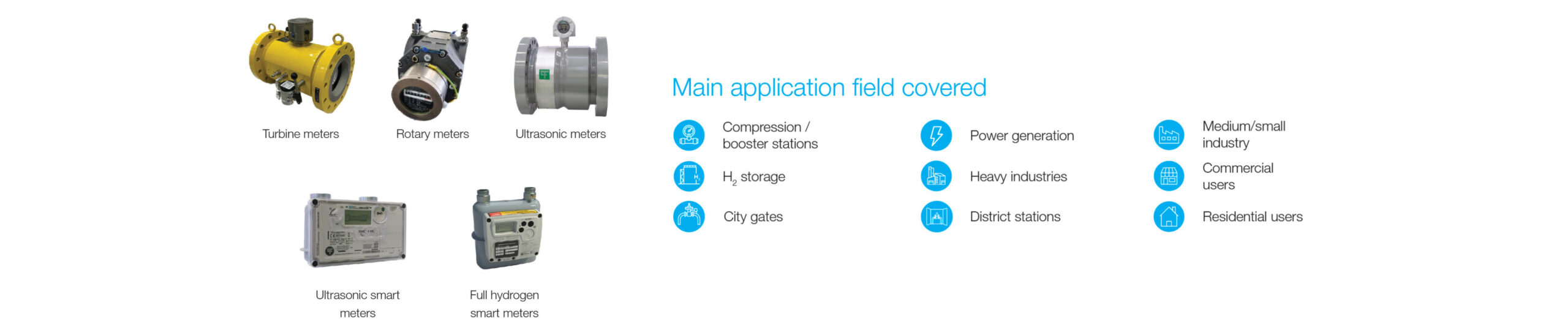

Accurate gas metering is a primary requirement for the energy sector. Pietro Fiorentini Group provides a complete range of gas meters for residential, commercial and industrial applications. Pietro Fiorentini Group guarantees the all the current manufactured gas meters are suitable for 20% hydrogen blending service.

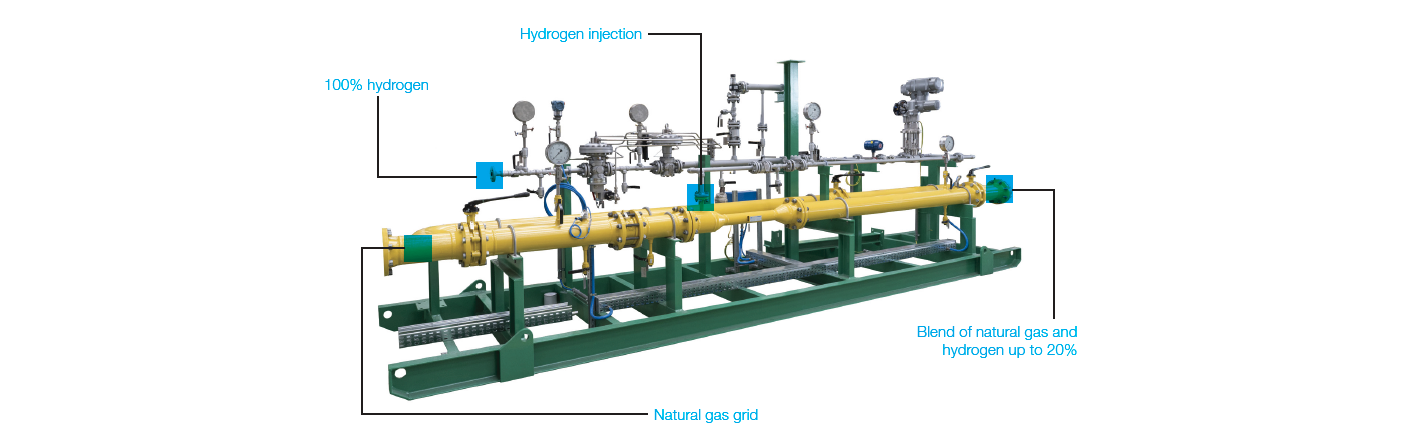

We provide tailor designed station for blending & injection, featuring a full scale industrial design that can be easily adapted from low pressure districts up to high pressure transportation networks and industrial applications.

Pietro Fiorentini hydrogen projects

Download the document